Aluminum ship doors have become increasingly popular in the maritime industry due to their resistance to corrosion. The use of aluminum in ship doors can help to significantly reduce maintenance costs and increase the overall lifespan of the doors. This is particularly important in the harsh marine environment where ships are constantly exposed to saltwater and other corrosive elements.

Aluminum is a non-ferrous metal that is known for its high resistance to corrosion. Unlike steel, which can rust when exposed to moisture, aluminum forms a protective oxide layer on its surface when exposed to oxygen. This oxide layer acts as a barrier against further corrosion, making aluminum doors highly resistant to rust and deterioration.

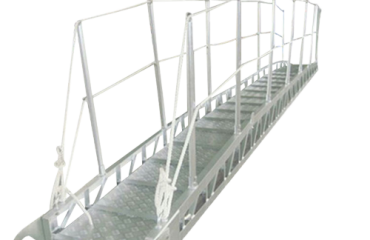

In addition to its corrosion resistance, aluminum ship doors also offer other advantages. They are lightweight yet strong, making them easy to handle and install on ships. This can help to reduce the overall weight of the vessel, improving fuel efficiency and reducing operating costs.

Aluminum doors are also highly customizable, allowing ship designers to create doors that meet the specific requirements of different ship types and configurations. They can be easily fabricated into various shapes and sizes, making them suitable for a wide range of applications on board ships.

Aluminum is a sustainable and environmentally-friendly material. It is highly recyclable and can be reused multiple times without losing its properties. This makes aluminum ship doors a more environmentally-friendly choice compared to doors made from other materials.

Despite these advantages, there are some limitations to using aluminum ship doors. Aluminum is not as strong as steel, which may limit its use in certain high-stress applications. It also tends to have a higher initial cost compared to other materials, although this can be offset by the long-term cost savings due to reduced maintenance requirements.